Pyrolysis

Pyrolysis technology provides ecologically sustainable way to dispose organic waste with minimized carbon footprint. Pyrolysis itself is an old innovation but making oil, carbon black and other valuable materials is relatively new but already proven technology.

We believe that recycling shall be feasible. The products made with recycling should be attractive to buyers, well designed, reasonably priced and safe – shortly they should be competitive in the market with virgin products. This should be possible with minimum or none financial support to recycling. And actually this is the direction we are going to, since raw material prices will go up due to lack of them and on the other hand recycled products are gaining more environmentally conscious fans all over the world.

Pyrolysis is an effective way to process organic waste - in principle any kind of waste beginning from foodstuff and ending to plastic waste. This is possible since pyrolysis – thermal treatment of organic feedstock in absence of oxygen – is very insensitive process. It is not necessary to separate paper from plastics 100 % or take out all pieces of metal and glass or food surplus. All this can be simple processed together.

Adamatic has developed and patented continuous pyrolysis processing system that is highly automated, effective and safe. This process can be tailored to process very different kind of feedstock – plastics, bitumen roofing, and agricultural waste. Many different kind of feedstock previously classified as “waste” can be successfully and economically processed to new valuable products.

The process

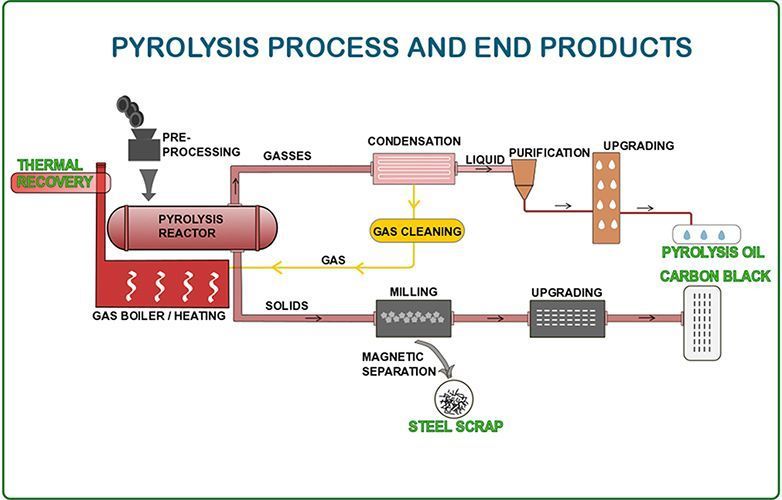

Pyrolysis is a process where (raw) material is heated in closed, oxygen-free chamber. Organic material is not burnt (oxidised), but gasified into syngas, which is condensed mostly into fuel oil. Lightweight hydrocarbons like methane and ethane remain gaseous and are used for heating the process. Remaining solids, carbon and steel are separated, cleaned and upgraded into products that can be reused in industry.

Engineering

Adamatic provides full engineering services, we can provide just complete engineering of a plant or part of it – or we can offer a turnkey delivery of multi-production line factory including run-up and training of staff. Our flexibility in delivery scope provides opportunity to use local manufacturers and suppliers as subcontractors.

Our standard pyrolysis unit is a module being able to process from 5 tons to 15 tons of material per 24hours. Production line is fully automated, just one man can run the process.

Engineering, materials, automation, safety and emissions are all according to EU-standards – production lines are CE-marked and tested. We are proud that the system we are offering is using the latest technology – and we are developing the machinery on constant basis. We have also applied for patents to some essential part of our technology.

Production plant is based on module pyrolysis units, the production capacity is increased by adding the number of module pyrolysis units. The modular system provides advantages in maintenance, training, production planning and stability of production.